Pick & Place

Pick and place robots utilize sensors, advanced vision technology, and a robotic arm to pick an object from one location and drop it in another

Machine Tending

Machine tending robots represent a significant evolution in the automation of manufacturing processes. Robot arms can easily be programmed to automatically handle the loading and unloading of machines, such as CNC machines, that require consistent feeding of raw materials

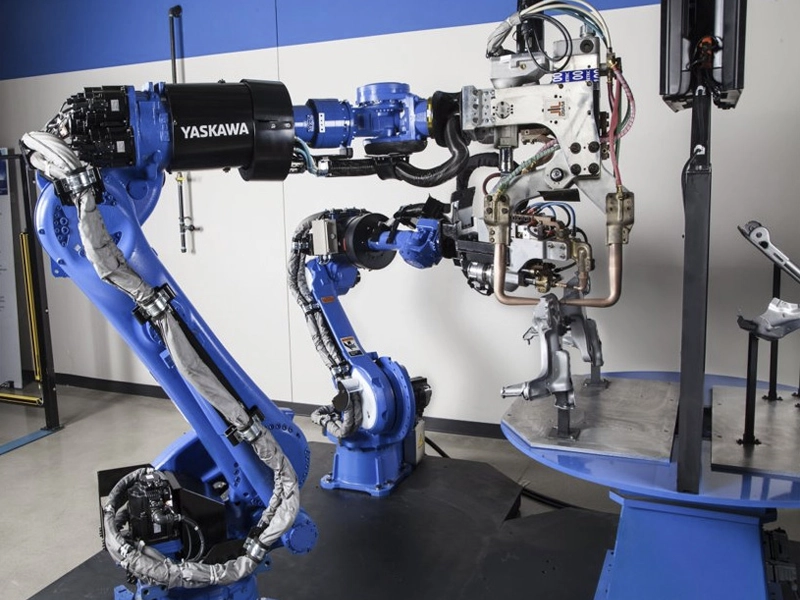

Spot Welding

Spot welding robots offer an exciting opportunity for many other modern manufacturers looking to significantly upgrade their manufacturing processes

Palletizing

Palletizing automation can boost the speed and efficiency of the production process, as automated machines can palletize boxes

MIG/MAG/TIG WELDING SYSTEM

Safety is one of the most important factors, and welding robots ensure operational continuity. Robotic welding guarantees result repeatability and welding production efficiency

Robotic Painting

Uniformity of coating - robots can move at a constant speed far better than a person and thereby ensure an even coating. Precision of application - the robotic painting arm moves with great accuracy. The position of the robot will be much more precise and repeatable than with a human painter.

TOUCH SCREEN TESTING

Testing With a 1, 2 or 3-fingered custom end effector and add-ons that emulate any multitouch gesture like tapping, pinching, swiping, and rotating, two high-resolution cameras, computer vision API, and alongside powerful electronics and robust engineering, the device testing robot easily replicates user interaction

ROBOT BASED VISION SENSOR 2D AND 3D

A vision sensor is utilized to automate the bin picking of workpieces. The sensor can identify parts with complex shapes or metallic parts which oil is adhered to.

Grinding & Polishing

Robotic sanding, robotic grinding, and other finishing and material removal jobs can be dangerous and pose serious hazards to people’s health and safety. Using our robots for these jobs improves safety by eliminating health hazards, while also providing manufacturers with a solution to labour shortage problems often seen in these applications

Robotics Foundry and Forging Application

Foundry Industrial Robotics Automation are engineered to perform a variety of tasks Casting Pouring molten metal into moulds with precision to ensure consistent quality and reduce wastage Handling Moving heavy and hot materials or components, which helps in reducing human labour and improving safety.

AMR And AGV

AMR a valuable addition to various industries, enhancing efficiency, safety, and overall productivity and material transport, AGV help streamline workflows, reduce idle time, and increase overall efficiency.

Sugrical Robot

Minimal blood loss

Pain less surgery

Fast Recovery

Cost effective Robotic surgery

Safest way of doing knee replacement surgery

Laser cutting and bone drill operation